8

/ Canadian Government Executive

// February 2016

ing a $1,200 plane ticket. The waste of

“Defects” was prominent in this situation,

consuming many more hours of human

capacity than it should have.

By eliminating defects in the process,

staff were able to dramatically reduce

preventable work, freeing up close to 50%

of the capacity previously required, on a

majority of its volume. As an added ben-

efit, this resulted in shorter lead times and

thus lower airfares by avoiding last-min-

ute booking costs.

How did they do it?

Identify and eliminate the root causes

of defects:

During the Lean project, the

team determined that users failed 80% of

the time to complete the application form

successfully, causing major preventable

work, because the form was:

• Written in “expert”, not common lan-

guage;

• Written with overly broad questions

that did not prompt or “nudge” the user

into the correct answer, the first time;

• Wordy, lengthy, and not understandable

Management

“at a glance”, so users would give up and

submit a hastily-completed form instead

of taking the time to figure it out;

• Multiple forms for different types of re-

quests resulted in some forms not being

filled out, or being filled out incorrectly.

After running focus groups to identify the

causes of recurring errors and usability of

the current forms, the team was able to

simplify, consolidate and error-proof them

to make them intuitive and easier to use.

Piloting and adjusting the new prototype

forms with small groups of real, typical us-

ers, proved that they would save consider-

able effort and led to a successful launch.

Tip: If you are trying this on your own,

make sure that you run your focus groups

with typical users, not your most-experi-

enced or best users. While your “power us-

ers” might be easy to recruit, they probably

have learned how to use imperfect forms.

On the other hand, if the least-successful

users can get the task done correctly with

your new prototype form, then the proto-

type form will likely work for everyone.

By eliminating defects in

the process, staff were able

to dramatically reduce

preventable work, freeing

up close to 50% of the

capacity previously

required, on a majority of

its volume. As an added

benefit, this resulted in

shorter lead times and thus

lower airfares by avoiding

last-minute booking costs.

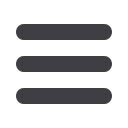

The later it is identified, the higher the cost of a defect